The washing equipment we manufacture is based on innovative solutions that significantly improve your production processes. By choosing to work with us, you benefit from a complete solution entirely adapted to your needs.

Small width ultrasonic machine

Cleaning machines for Anilox labels

The anilox roll is at the heart of the flexographic printing process.

Optimizing its performance is essential to obtain the best quality printing.

The latest engraving techniques make it possible to manufacture better quality cylinders, with finer wefts and deeper cells.

However, regular cleaning and maintenance is required to ensure the cylinder performs to specification.

Cleaning 1 to 8 cylinders at a time. Single or Double frequency. The most suitable solution in terms of cleaning quality, cost price and space for Flexo label printers.

''The ultrasounds spread evenly and constantly in the ultrasonic bath to clean and unclog all the parts removable helio and flexo, cylinders, anilox, doctor blade chambers, ink recirculation tanks smeared with water or solvent inks, UV varnish or glues''

adcnetflexo.com

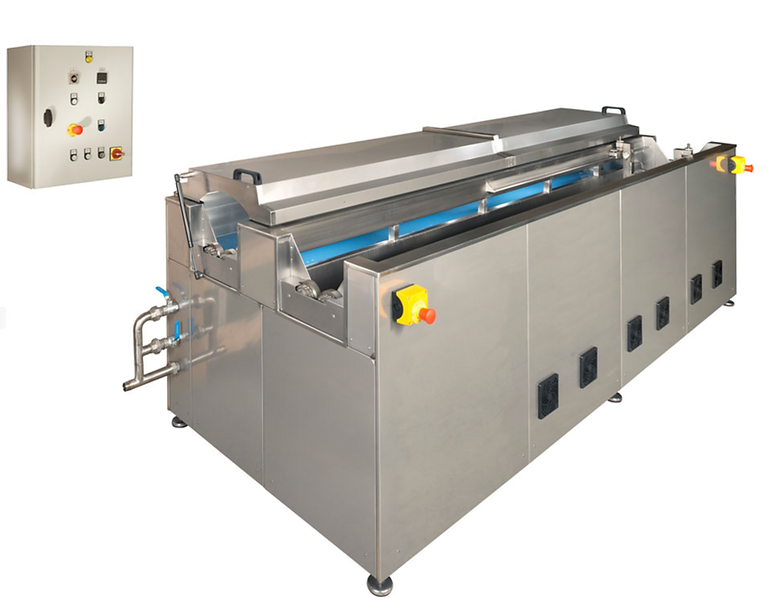

ADC CLEANER 3000 Wide Width Ultrasonic Machine

Cleaning machines for Anilox sleeve & Anilox shaft

The ultrasonic cleaning of Aniloxes is one of the most effective because it combines both mechanical and chemical effects. In fact, if the cleaning product is used to dissolve or soften the inks to the bottom of the cells, the ultrasounds are used to suck the dissolved inks out of the cells and this without danger for the Anilox.

We have various standard or custom models for cleaning your Anilox.

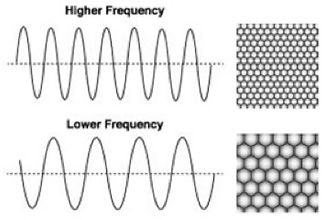

The standard models are equipped with 50 kHz with an optional second frequency of 100 kHz for higher frequency.

DUAL FREQUENCY

50kHz standard and 100 kHz

for the lineatures HD

How does ultrasound work?

A high-frequency current from an electricity generator powers an ultrasonic transducer, the functional element of which consists of two piezoceramic plates. The transducer is attached to the bottom or wall of the bath and causes vibrations which are transmitted to the washing liquid. Rapid thickening and dilution of the liquid causes cavitation, that is, the rapid formation and disappearance of microbubbles under vacuum that cause intense but controlled detachment of dirt particles throughout the volume of the liquid.

This is the effect of ultrasonic vibration on the surface of the cleaning product:

The modern ADC ultrasound generator-912A is equipped with functions:

ultrasonic power adjustment

automatic adjustment of the resonant frequency

power and frequency visualization

list and identification of alarms

possibility of master control

possibility of equipping with a scanning system

Anilox cleaning intended parquet print

cylinder weight 900 KGS

U 3000

Benefits of Ultrasonic Cleaning

Ultrasonic cleaning achieves maximum cleanliness in less time than conventional cleaning methods such as hand washing, spray washing or others.

Ultrasonics effectively removes contaminants such as inks, varnishes, glues, grinding and polishing pastes, abrasives, swirls and filings, lubricants and cooling emulsions. Although cavitation caused by ultrasound has an intense effect, it does not damage delicate or complex mechanisms. Cleaning requires minimal supervision and can be carried out by unqualified personnel.

Ultrasonic washers can be easily adapted for mass production by connecting them to a production line.

AUTOMATIC WASHING SYSTEM

TYPE U1000 ULTRASONIC with

lowering/lifting system

Range of units featuring a lifting/lowering system.

The machine can consist of several tanks, for example for washing, rinsing and drying.

The transport system between the tanks can be manual or automatic.

ADC CLEANER Spraying HP

This type of machine can have a vertical or horizontal axis of rotation. This type of washer can be equipped with several operations: washing, rinsing, drying.

The loading and unloading system can be manual or automatic. Additional equipment is configured according to customer needs.

Other sectors of activity

ADC CLEANERS ULTRASONIC

The ultrasonic cleaning machine in aqueous solution in its standard version includes ultrasonic washing in a temperature bath, then two rinsing phases, followed by drying in hot dry air. They meet the needs of many industries such as aeronautics, automotive, precision mechanics or electronics. Closed-loop rinsing with pure de-ionized water ensures organic and ionic cleanliness beyond military requirements.

ADC CLEANERS include as standard cleaning jets immersed in all the washing and rinsing tanks which are equipped with a weir to evacuate the impurities on the surface.

The options offered:

-

A preliminary cleaning step equipped with an oil separator or oil separator for very dirty parts

-

Installation of ultrasound in the rinsing tanks

-

Vertical agitation at all stages of cleaning or rinsing.

-

Hot air dryer accommodates two baskets to increase production volume

-

Automated basket movement

Alliance of spray-ultrasound technologies

The machine is designed to be able to wash complex shaped parts. The process is fully configurable and can consist of several steps: pressure washing, ultrasonic washing, rinsing (possibly several rinses) by pressure and ultrasonic, drying (optionally vacuum drying). Immersion washing has an adjustable immersion level (>1/2 basket, full basket). Combined with the rotation of the basket or the pendulum function, it is possible to wash the parts in the smallest corners. The advanced bath filtration and de-oiling system significantly extends the bath change interval.

The machine is capable of achieving a very high level of part cleanliness. Purity complies with ISO 16232 and VDA 19.1 standards.

Visualization of process data on the operator panel allows full control of the process. The unit allows you to observe (the indicator light and chamber lighting are installed) and change the speed of the basket, the temperature and pressure inside the chambers, as well as the level of filter wear.

The arrangement of connections, controls, etc. is agreed with the customer. The ergonomic and well-thought-out design of the machine allows easy access to all components of the unit, allowing for quick and easy maintenance.

CLEANING YOUR FLEXOGRAPHIC PLATES,A

DC CLEANER SP SERIES

with 3 brushes, (2 ROTARY AND 1 FLAT) available in sizes 46-70-90-120-150.

Made of painted steel, painted steel and stainless steel or all stainless steel version.

Equipped with PLC electronic system and touch screen control panel.

Allows you to automate the cleaning system and achieve better results with consistently high quality standards.

Rationalizes the use of chemicals, guaranteeing greater respect for the environment and cost control.

Easy to use, with intuitive automated controls.

It is a machine with high performance and robustness, which guarantees correct and efficient operation for several years, allowing the investment to be fully amortized.

It can be equipped with the following options: automatic conveyor, motorized entry table with conveyor and exit table, evacuation of the liquid solution, porthole in the upper casing to inspect the interior of the machine during processing, assistance system from a distance.

Ink trays, doctor blade chambers and rollers always ready for use!

ADC CLEANERS is the line of spray systems designed for the flexo printing industry.

These machines are robust, easy to use, precise and quick to clean without special maintenance.

The ADC CLEANERS HP series machines do not use solvents and do not require any special preparation because they use detergents and not solvents.

These are ready-to-use, non-flammable products whose characteristics comply with the most restrictive standards in the food sector.

The ADC CLEANERS series systems are the result of paying attention to printers' problems.

ADC CLEANERS HP can clean platens, ink trays and doctor blades in minutes.

Options are available for washing buckets, flat and rotary screen printing frames (Chablons).

ADC CLEANERS -

SHP Anilox & Sleeves & Flexo plate sleeves

available in sizes 800 -1000 -1700-2500 - 3400 - 4000 Made in two versions: painted steel and stainless steel.

It can be equipped with various elements, including the additional carriage that allows the simultaneous insertion of two consecutive aniloxes.

The process is carried out by washing with detergent, discharging it into the recirculation system provided for this purpose, rinsing with water and drying.

anilox & sleeves